PJSC Evropeyskaya Elektrotekhnica's operating results for 2019

PJSC Evropeyskaya Elektrotekhnica's operating results for 2019

March 3, 2020. Moscow — PJSC Evropeyskaya Elektrotekhnica (hereinafter, the "Company") publishes its operational results for 2019.

The Company would like to present its results and business development prospects in its key fields:

-

Engineering Systems,

-

Process Systems.

The Company's business model was presented in its 2018 Annual Report (see pages 26–27).

PJSC Evropeyskaya Elektrotekhnica's current key performance indicators:

|

Indicator |

UOM |

2019 |

2018 |

Change |

|

Share of own production in the total volume of deliveries |

% |

49% |

35% |

+14 p.p. |

|

Share of exports |

% |

9% |

11% |

–2 p.p. |

|

Number of engineering centers in the Russian Federation and abroad at the end of the period (change in number for the period) |

N |

17 (+1) |

16 (+3) |

+1 |

|

Investments |

RUB mln |

214 |

407 |

–47.4 % |

|

Investment in R&D |

RUB mln |

74 |

165 |

–55.2 % |

|

Indicators of sustainable development: |

|

|

|

|

|

· volume of energy-efficient (energy-saving) equipment, environmentally-friendly equipment and materials delivered |

RUB mln |

1,240 |

532 |

+133.1% |

|

· number of personnel injuries |

N |

0 |

0 |

- |

Statement from Management

Ilya Kalenkov, General Director of PJSC Evropeyskaya Elektrotekhnica, commented on the published results:

Engineering Systems:

Last year, the Company has traditionally continued its work in the segment of high-quality products and services. The selected approach guarantees stable attractive profitability in this field.

We continued to develop a network of engineering centers in Russia and abroad. In the past year, a number of these centers (Moscow, St. Petersburg, Ufa, Kazan, Tyumen) demonstrated the ability to not only successfully find new customers in the engineering field, but also to promote process equipment.

In Q4 2019, 342 new contracts in the amount of RUB 1,769.7 million were added to our Company order portfolio. To put this in perspective: the Company's consolidated revenue as of the results of 3 quarters of 2019 amounted to RUB 2,561 million (IFRS).

The stagnation seen in 2017–2018 in the domestic economy is being compensated for, and the amount of major projects in manufacturing and infrastructure continues to grow. This has a beneficial effect on the Company's total project portfolio. Russian customers are engaged in import substitution in a measured way, with high quality European industrial equipment and materials still being used in a large number of manufacturing projects.

The number of projects we implement in the Far East of Russia keeps growing. For example, we are involved in massive projects for the construction of Amur GPP and Amur GCC. To this end, we began to actively work at the Far East sites in Blagoveshchensk. We are working on the possibility of creating new engineering centers in Vladivostok, Krasnoyarsk or Chita (one of the examples of large industrial projects located nearby is the project by Metalloinvest in Udokan).

As of the end of 2019, the Company opened its 17th engineering center. This center commenced its work in Quito, the capital of the Republic of Ecuador (South America). This center specializes in services in the field of Process Systems, and in the introduction of environmentally friendly technologies in the emerging local oil industry. We hope that cooperation with customers from Ecuador and neighboring countries (e.g., Colombia) will bring new contracts in 2020 and in the coming years, mainly in the field of innovative oil processing plants.

This segment forms a stable segment of consolidated revenue for Evropeyskaya Elektrotekhnica Group of Companies. Extensive diversification of our income by customer, by geography, and by product type reduces sensitivity to adverse external or local shocks (macroeconomics, black swans, challenges related to individual customers).

Process Systems:

Creating "traditional" Oil&Gas field processing equipment

As of the end of 2019, the Company has successfully passed certification and accreditation procedures with major customers from the Oil&Gas sector from Russia, Uzbekistan, and other countries.

The company's certification process has been initiated to ensure compliance with the API (American Petroleum Institute) standard. An entrance audit of the Company's readiness to implement the standard was conducted, and a roadmap was prepared to meet the necessary requirements. This is important for launching projects in the markets of the Persian Gulf, Middle East, Africa, Central and Latin America.

In Q4 2019, a major client of the Company decided not only to buy out the property of the previously rented mobile preliminary water knock-out unit, but also purchased a second similar unit with a higher performance rate. This equipment ensures the environmentally safe extraction of oil from the well fluid. Its use allows oil companies to avoid economically pointless pumping of ballast water over dozens of kilometers. This reduces the risk of accidents at oil fields, and reduces the likelihood and extent of possible environmental damage.

The company also receives additional revenues from manufacturing critical components for the repair of imported oil and gas processing equipment, for example, the manufacture, delivery and launch of a heat pipe for a heater treater unit by a foreign producer.

Application of innovative equipment

The practice of operating the first innovative units in the Middle East (fuel oil savings in the energy and cement industry) showed that: a more significant incentive for cooperation with our Company is often not even a financial benefit, but a pronounced positive environmental effect — the possibility to drastically reduce dangerous emissions from boilers (ovens) into the atmosphere, thereby dramatically improving the environmental situation in the region of operation of this equipment, which in most cases is already morally and physically outdated. The operation of our equipment confirmed the following: soot emissions were significantly reduced. This is perfectly visible, as the pipes on site no longer emit thick smoke into the air. Other hazardous emissions, including nitrogen oxide and carbon monoxide, were significantly reduced.

In 2018–2019, the experience and efforts of two teams — electrical engineers and process equipment specialists — allowed us to complete a number of environmentally friendly development projects with high market potential:

- Fuel oil desulfurization unit

o R&D for this type of units were successfully completed;

o Demand for this equipment is based on the following facts:

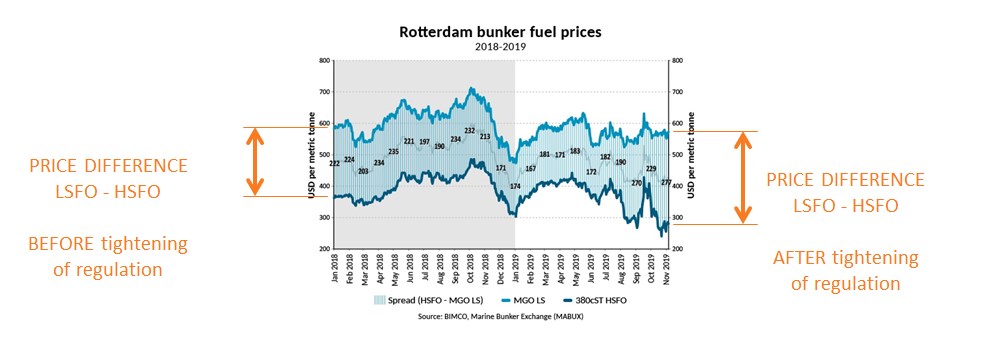

- there is a gradual reinforcement of regulations on the international market — the growth of IMO requirements for the share of sulfur (no more than 0.5%) in bunker fuel oil; the global scale of this market: 3.5% sulfur fuel oil (HSFO) was used as fuel by more than 70 percent of the global fleet until 2019, its annual consumption exceeds 200 million tons (source);

- large volumes of sulfur fuel oil on the global market, whose use is restricted and price severely decreased due to that; desulfurization of such fuel oil significantly increases its market value;

- throughout 2018–2019, the price of low sulphur fuel oil (LSFO) grew 2 times higher than the price of high sulphur fuel oil (HSFO), while this difference amounted only to 60% two years ago:

- the use of equipment for desulfurization of fuel oil does not require major financial investments from the Partners of our Company: cooperation between our Company and our Partners in this field — on terms of equipment leasing and division of the financial result;

- it is possible to arrange desulfurization in the vicinity of consumers — in ports (which is important, for example, for bunker companies);

- Units for fuel oil/fuel savings

o Commissioning of the units at three thermal power plants in Ecuador is underway; expected launch date for state testing is March 2020;

o Successfully completed legal and organizational stages of launching new equipment in Ecuador;

o An agreement was reached with MurmanEnergoSbyt on the pilot implementation of this type (state testing of the equipment is planned for March 2020); these units should become a reference for future Russian Partners;

o Negotiations with a great number of Partners in Russia and abroad are ongoing;

- Unit for increasing octane fuel

o We plan to launch a reference unit of this type in Q2 2020 at the site of our Partner in Tomsk; this location is beneficial for us due to the availability of raw materials in the form of gas condensate that is initially sulfur free. We expect to ensure the quality of the output product (gasolines) to up to Euro 5 in terms of sulfur content.

These units are implemented in the form of mobile process solutions.

The units are integrated into the technological chains of the Partner companies (power plants, industrial consumers, boiler houses). This protects the Company interests, and ensures consistency between the Company's and the Partner's interests for the long term.

The legal regulation for the use of new developments has been defined, and specific practical measures for the protection of the Company's intellectual property were insured in relation to new equipment (remote control over equipment, service — exclusively by the specialists of our Company).

About Evropeyskaya Elektrotekhnica Group of Companies

• Evropeyskaya Elektrotekhnica Group of Companies (MOEX: EELT) offers comprehensive solutions in the field of engineering and technological systems for industrial, construction and infrastructural purposes: low and medium voltage distribution equipment, low current systems, lighting systems, industrial electric heating systems and equipment for the Oil&Gas and petrochemical industries.

• As a Russian joint-stock company with high corporate governance standards and financial sustainability, the Company's Mission is to improve people's quality of life with its entrepreneurial vigour and engineering competencies.

• The Company was founded in 2004 and unites a distribution center, engineering departments, an electrical laboratory and specialized production facilities. The company is one of the largest electrical equipment distributors in the Russian Federation and an industrial partner of leading companies on the international engineering market.

• The Company's logistics capabilities include delivery (including non-standard and oversize load) to customers throughout Russia, including hard-to-reach Northern areas, as well as to Central Asia, North Africa and the Middle East.

• The Company has its own production of the following equipment:

-

Complete transformer substations;

-

Medium voltage units;

-

Low voltage panels of up to 6,300A (including metro solutions);

-

Electric lighting systems;

-

Industrial electric heating systems;

-

Cabling and wiring products.

• Areas of application of the Company's competences:

-

Oil&Gas industry;

-

Electric power sector;

-

Peaceful atom,

-

Steel and mining industry;

-

Engineering;

-

Transport infrastructure, water supply and sanitation.

• Evropeyskaya Elektrotekhnica's customers include major Russian companies: Rosneft, Gazprom, NOVATEK, LUKOIL, Sibur and Nizhnekamskneftekhim. Supplies were successfully implemented for the following projects: Power of Siberia, Yamal LNG, Smolensk NPP, Data Center of Sberbank of Russia, the Domodedovo, Sheremetyevo, and Pulkovo Airports, etc.

• New areas of Company activity starting from 2018 include development and production of the following:

-

Modular equipment for the Oil&Gas and petrochemical industries (Company subsidiary ROG-Engineering, Ufa, Republic of Bashkortostan, Russian Federation);

-

Industrial specialized solutions for metro substations (currently being consolidated into the Group's structure: Metrotonnel, Moscow, Russian Federation);

-

Industrial electric heating systems.

• Key financial indicators of PJSC Evropeyskaya Elektrotekhnica (IFRS):

|

|

Revenue (RUB billion) |

Profit for the period (RUB million) |

Assets (RUB billion) |

| 9 months of 2019 |

2.60 |

239.2 |

1.72 |

|

2018 |

3.29 |

293.1 |

1.29 |

|

2017 |

2.60 |

134.7 |

1.15 |

350 people – the personnel headcount.

EELT – the trading code for common shares of PJSC Evropeyskaya Elektrotekhnica on the Moscow Exchange, where shares are traded since September 2017.

BBB- (RU), stable outlook – the credit rating of PJSC Evropeyskaya Elektrotekhnica is at the investment level; the rating confirmed by ACRA on January 30, 2020.

Contacts:

PJSC Evropeyskaya Elektrotekhnica

Tel.: +7 (800) 600-71-18

Mailing address: 1 Lyotchika Babushkina Street, Building 3, Moscow, 129344

|

Press contacts

|

Contact for investors and analysts

|

For more information, please contact:

Stanislav Martyushev

Director for Corporate Communications and Investor Relations

PJSC Evropeyskaya Elektrotekhnica

Tel. +7 (495) 660-71-18 ext. 164

Find us on social media:

FACEBOOK TWITTER INSTAGRAM VKONTAKTE LINKEDIN YOUTUBE